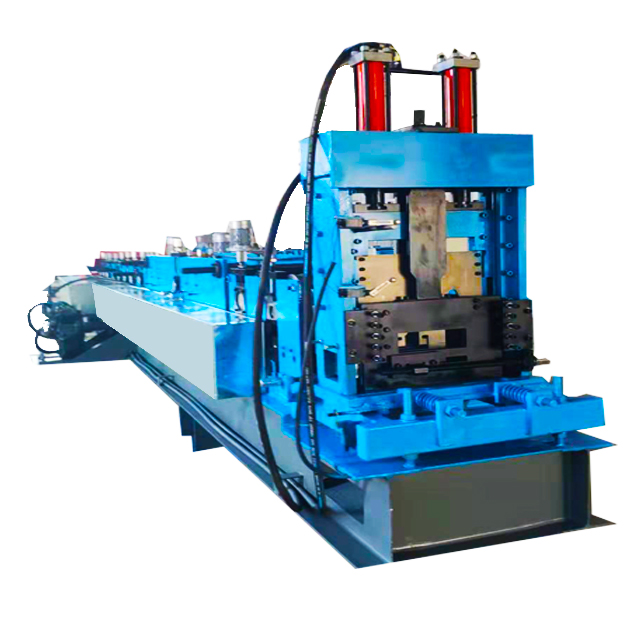

High-Quality Steel Roll Forming Machine for Your Production Needs

By:Admin

In a world where technology and innovation are constantly evolving, {Company Name} stands out as a leading manufacturer in the field of roll forming machinery. With a commitment to excellence and a focus on meeting the needs of their customers, {Company Name} has established itself as a pioneer in the industry.

The Color Steel Roll Forming Machine is one of the latest developments from {Company Name}. This state-of-the-art machine is designed to produce high-quality color steel roofing and wall cladding products with precision and efficiency. With its advanced features and cutting-edge technology, the Color Steel Roll Forming Machine is revolutionizing the way steel products are manufactured.

One of the key features of the Color Steel Roll Forming Machine is its versatility. It is capable of producing a wide range of color steel products, including corrugated roofing sheets, wall panels, and a variety of architectural profiles. This flexibility makes it an ideal solution for manufacturers who require different types of color steel products for various applications.

In addition to its versatility, the Color Steel Roll Forming Machine is also known for its high-speed production capabilities. With its advanced automation and control systems, the machine can produce large volumes of color steel products in a short amount of time, without sacrificing quality. This efficiency not only increases productivity for manufacturers but also reduces production costs, making the machine a cost-effective solution for businesses.

Furthermore, the Color Steel Roll Forming Machine is designed with durability and reliability in mind. {Company Name} has utilized the latest engineering techniques and materials to ensure that the machine can withstand the rigors of continuous use in an industrial setting. This durability not only extends the lifespan of the machine but also minimizes downtime for maintenance, maximizing productivity for businesses.

Another noteworthy aspect of the Color Steel Roll Forming Machine is its user-friendly design. {Company Name} has prioritized ease of use and accessibility in the development of this machine, making it simple for operators to set up, operate, and maintain. This intuitive design not only reduces training time for employees but also minimizes the risk of errors and accidents, leading to a safer working environment for all.

Additionally, {Company Name} offers comprehensive support and service for the Color Steel Roll Forming Machine, ensuring that customers can maximize the potential of their investment. From installation and training to ongoing maintenance and technical assistance, {Company Name} is committed to being a reliable partner for its customers, providing peace of mind and confidence in their machinery.

{Company Name} has a rich history of innovation and success in the roll forming machinery industry. With a team of skilled engineers and experts, the company continues to push the boundaries of what is possible in manufacturing technology. The Color Steel Roll Forming Machine is just one example of {Company Name}'s dedication to excellence and a testament to its position as a trailblazer in the industry.

In conclusion, the Color Steel Roll Forming Machine from {Company Name} represents a significant advancement in the field of roll forming machinery. Its versatility, speed, durability, and user-friendly design set it apart as a superior solution for manufacturers seeking high-quality color steel products. Furthermore, {Company Name}'s commitment to customer support ensures that businesses can rely on the machine to meet their production needs with confidence. As {Company Name} continues to lead the way in innovation, the Color Steel Roll Forming Machine stands as a testament to the company's dedication to excellence and its ongoing contribution to the manufacturing industry.

Company News & Blog

High-Quality Three Layers Color Steel Roll Forming Machine for Sale

The global construction industry is constantly evolving with new technologies being introduced to increase efficiency and productivity. One such innovation is the Three Layers Color Steel Roll Forming Machine, a state-of-the-art solution for producing high-quality color steel sheets for various building applications. This advanced machine is designed to meet the increasing demand for durable and aesthetically pleasing building materials, making it an essential tool for construction companies around the world.The Three Layers Color Steel Roll Forming Machine, offered by {}, is a versatile and efficient solution for manufacturing color steel sheets with three different layers to enhance their performance and visual appeal. With its precision-engineered design and advanced technology, this machine can produce color steel sheets of various thicknesses, lengths, and colors to meet the specific requirements of different construction projects. Its ability to form three layers of steel sheets in a single process significantly reduces production time and costs, making it an ideal choice for large-scale construction projects.The machine's key features include a robust frame, precise roller design, and advanced control system, providing smooth and accurate sheet forming with minimal material waste. Additionally, its automated operation and user-friendly interface make it easy to operate and maintain, ensuring consistent and reliable production quality. This makes the Three Layers Color Steel Roll Forming Machine a valuable asset for construction companies looking to streamline their production processes and deliver high-quality color steel sheets to their clients.In addition to its superior performance, the Three Layers Color Steel Roll Forming Machine is also designed with environmental sustainability in mind. By optimizing material usage and reducing energy consumption during production, it helps minimize the machine's environmental impact, aligning with the global push towards greener construction practices. This makes it a responsible choice for companies committed to sustainable development and eco-friendly construction solutions.With its impressive capabilities and environmental benefits, the Three Layers Color Steel Roll Forming Machine is gaining traction in the global construction industry. From roofing and cladding applications to wall panels and structural components, this machine is proving to be a versatile and cost-effective solution for meeting the growing demand for high-quality color steel products. Its ability to customize sheet thickness, length, and color adds a layer of versatility that is resonating with construction companies looking to differentiate their offerings in the market.As a leading provider of roll forming solutions, {} is dedicated to delivering cutting-edge technologies that empower construction companies to achieve their production goals with precision and efficiency. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted partner for construction companies seeking reliable and advanced roll forming equipment. The Three Layers Color Steel Roll Forming Machine is a testament to {}'s commitment to pushing the boundaries of what's possible in the construction industry, offering a solution that combines performance, versatility, and sustainability in one powerful package.In conclusion, the Three Layers Color Steel Roll Forming Machine is a game-changer for the construction industry, offering a comprehensive solution for producing high-quality color steel sheets with unmatched efficiency and precision. As construction companies continue to seek innovative technologies to improve their production processes, this advanced machine is poised to play a pivotal role in shaping the future of building material manufacturing. With its exceptional performance, environmental responsibility, and versatile capabilities, the Three Layers Color Steel Roll Forming Machine is set to become a cornerstone of modern construction practices.

Top-Quality Color Steel Roll Forming Machine for Sale - Roof Panel Roll Forming Machine

Title: The Versatility and Efficiency of Color Steel Roll Forming Machines in ConstructionIntroduction:In today's ever-evolving construction industry, the adoption of advanced machinery and technology plays a crucial role in streamlining processes and ensuring high-quality results. One such machine that has gained immense popularity is the Color Steel Roll Forming Machine. Let's delve into the versatility, efficiency, and benefits of this essential tool for modern construction projects.What is a Color Steel Roll Forming Machine?A Color Steel Roll Forming Machine is a specialized equipment used to transform flat metal sheets into desired shapes by passing them through a series of rollers. This process, known as roll forming, allows for the creation of sturdy and precise steel profiles, commonly used in roofing, wall cladding, and other structural applications.Versatility and Applications:One of the significant advantages of the Color Steel Roll Forming Machine is its versatility. With adjustable settings, it can produce a variety of steel profiles with different widths, lengths, and thicknesses. This adaptability makes it an ideal solution for a wide range of construction projects.1. Roofing Panels: The machine forms corrugated or trapezoidal profiles commonly used in roofing applications. These panels provide exceptional strength, durability, and weather resistance. Moreover, the roll forming process ensures consistent panel quality, promoting efficient installation and reducing material waste.2. Wall Cladding: Color Steel Roll Forming Machines can create attractive and functional wall cladding profiles. These profiles not only enhance the exterior aesthetics of buildings but also provide insulation, moisture protection, and soundproofing qualities.3. Purlins and Framing Members: The machine can also produce purlins and framing members for building structures. These components are essential for providing support, stability, and structural integrity.Efficiency and Benefits:1. Customization: Color Steel Roll Forming Machines enable customized design options. Through computer-controlled systems, operators can input specific measurements and produce steel profiles tailored to the project requirements. This customization minimizes material waste and optimizes resource utilization.2. Speed and Accuracy: These machines have high-speed production capabilities, ensuring a swift manufacturing process. The precise and consistent shaping of metal profiles guarantees uniform dimensions, minimizing installation issues and project delays.3. Cost-Effective: Utilizing a Color Steel Roll Forming Machine helps contractors save costs in various ways. The reduced labor required for roll forming, together with its high productivity, significantly lowers overall project expenses. Additionally, the longevity and low maintenance requirements of steel profiles minimize repair and replacement costs in the long run.4. Durability and Performance: Steel profiles manufactured by these machines exhibit exceptional strength and resistance to external factors. They are highly durable, offering long-lasting protection against extreme weather conditions, corrosion, fire, and impact.Conclusion:As the construction industry continues to evolve, the demand for efficient and versatile machinery like the Color Steel Roll Forming Machine increases. Offering customization, precision, and cost-effectiveness, this powerful tool provides various steel profiles essential for modern construction projects. Whether used in roofing, wall cladding, or structural applications, the Color Steel Roll Forming Machine stands as a testament to the industry's commitment to embracing advanced technology for better results.Keywords: Color Steel Roll Forming Machine, Roof Panel Roll Forming Machine, construction industry, roll forming, versatility, efficiency, roofing panels, wall cladding, purlins, framing members, customization, speed, accuracy, cost-effectiveness, durability, steel profiles.

Get High-Quality Steel Roll Forming Machines for Your Business

Mills and factories are in need of durable and long-lasting roofing solutions. The Ibr Color Steel Roll Forming Machine is the solution many of them have been looking for. The machine produces roofing sheets that are made from galvanized steel which is not only strong but also rust and corrosion-resistant. This makes them an ideal option for roofing in environments that experience high humidity or saltwater exposure.The machine is manufactured by one of the leading companies in the industry and it is designed to make the production of Ibr roofing sheets easy and efficient for any factory. The company has been in operation for many years and has built a reputation for producing high-quality machinery that delivers exceptional results.The Ibr Color Steel Roll Forming Machine is easy to operate and requires minimal maintenance. This makes it ideal for factories looking to increase their production while keeping costs low.The machine is capable of producing roofing sheets that are up to 6 meters long and come in a range of colors. The roofing sheets can also be customized to fit the specific requirements of each factory. This means that factories can create roofing solutions that are tailored to their unique needs.One of the key features of the Ibr Color Steel Roll Forming Machine is its speed. With a production capacity of up to 30 meters per minute, the machine can meet the demands of even the busiest factories. This makes it an ideal investment for factories that need to increase their production capacity.The machine is also equipped with safety features that ensure that the operation is safe for all workers. It has an emergency stop button that can be activated at any time, and its design ensures that workers are not exposed to any moving parts.The Ibr Color Steel Roll Forming Machine is also designed to be environmentally friendly. The machine produces minimal waste, and the roofing sheets that it produces are 100% recyclable. This means that factories can produce roofing solutions that are not only strong and durable but also environmentally sustainable.Overall, the Ibr Color Steel Roll Forming Machine is a great investment for any factory looking to increase their production capacity and improve the quality of their roofing solutions. With its speed, efficiency, and durability, the machine is a reliable choice for any factory in need of a roofing solution that will last for years to come.

Specialized Color Steel Roll Forming Machine Factory Offers Quality Production

Color Steel Roll Forming Machine Factory: Pioneering Innovation in the Roll Forming IndustryColor Steel Roll Forming Machine Factory has been at the forefront of innovation in the roll forming industry, since its inception in {}, specializing in the research, design and development of roll forming machines. The company has made a name for itself by providing high-quality, easy-to-use and low-maintenance roll forming machines to a diverse range of customers across the world.Innovation and technology remain at the heart of the company's operations, and it continues to invest heavily in research and development to develop new and exciting products for the market. The factory's engineers have years of industry experience and have developed a range of products and manufacturing processes that deliver high-quality roll forming machines to customers worldwide.The company's dedication to innovation and quality is manifested in its product lines, which feature both standard and customized roll forming machines to meet the needs of its customers. The product range includes C and Z purlin machines, roofing and wall cladding machines, high-speed roll forming machines, floor deck roll forming machines, sandwich panel machines, and other related products.The factory's products are known for their exceptional quality, durability, energy efficiency and low maintenance requirements, which make them popular among customers in construction, automobile, and various other industrial sectors. The factory has a stringent quality control process in place to ensure that all its products meet the highest quality standards before they leave the factory.To maintain its position as an industry leader, Color Steel Roll Forming Machine Factory continues to invest in modern technologies that enhance the quality and functionality of its roll forming machines. The company has state-of-the-art manufacturing facilities that feature the latest machinery, and automated processes that ensure precision and speed in production.The factory's management team and customer service representatives are committed to customer satisfaction, and they offer prompt post-sales support to ensure the longevity and optimal functioning of its products. The company has a wide network of distributors and sales agents in various parts of the world to provide efficient and timely customer service and support.The factory is also committed to environmental sustainability, and all its products are designed to be energy-efficient and eco-friendly. The company uses recycled materials where possible and invests in technologies that minimize its carbon footprint.Besides its core business, Color Steel Roll Forming Machine Factory is also involved in philanthropic activities aimed at giving back to the community. The company supports various charitable causes in the local community and has made donations to several institutions and organizations to promote education, health, and social welfare.In conclusion, Color Steel Roll Forming Machine Factory's dedication to innovation, quality, and customer satisfaction has established it as a leader in the roll forming industry. Its products are used worldwide, and it continues to pioneer new and innovative manufacturing processes to meet the needs of its customers. As the company moves into the future, its commitment to excellence in all areas of its operations will undoubtedly see it maintain its position as a leader and an innovator in the industry.

High-Quality Roll Forming Machines: Top Supplier and Manufacturer in China

Roll forming machines have been used in the construction and manufacturing industries for decades, particularly for producing profiles and panels that are used for roofing and cladding. There are different types of roll forming machines depending on the material being formed and the desired profile. Among these, the color steel roll forming machine is one of the most popular, especially for producing steel sheets in different colors.A color steel roll forming machine is a type of roll forming machine that is used to manufacture steel sheets in different colors. These machines are typically used for the production of sheets used for roofing and wall cladding, which are primarily used in the construction industry. The process of color steel roll forming involves feeding a coil of sheet metal through a series of rolls that shape the metal into the desired profile while applying a coating of paint or finishing material to the surface of the metal. The coating can be applied either before or after the forming process, depending on the type of machine being used.When it comes to purchasing a color steel roll forming machine, there are several factors to consider. First and foremost is the quality of the machine itself. A good machine will be made from high-quality materials and have a robust construction that ensures it can withstand the rigors of continuous operation. Additionally, the machine should be easy to operate and maintain, with user-friendly controls and clear documentation that makes it easy to troubleshoot any issues that may arise.Another important consideration when purchasing a color steel roll forming machine is the reputation of the manufacturer. There are many manufacturers of roll forming machines out there, but not all are created equal. Look for a manufacturer that has a good track record of producing high-quality machines, and that has positive reviews from other customers in the industry. This will give you confidence that you are getting a machine that will meet your needs and perform well over the long term.Finally, consider the price of the machine and how it fits into your budget. Color steel roll forming machines can be quite expensive, but there are many factors that can affect the price you pay, including the size and complexity of the machine, the materials used, and the quality of the components. Be sure to do your research and shop around to find the best value for your money.If you are in the market for a color steel roll forming machine, be sure to consider a reputable manufacturer like (brand name removed). With years of experience producing high-quality roll forming machinery, they have the expertise and know-how to help you select the perfect machine for your needs. Their range of products includes not only color steel roll forming machines but also a variety of other roll forming machines for a wide range of applications. So whether you need a machine for roofing, cladding, or other applications, they have you covered.In conclusion, a color steel roll forming machine is an essential tool for any construction or manufacturing business that needs to produce steel sheets in different colors. When shopping for a machine, it is important to consider quality, reputation, and price, and to choose a manufacturer that has a proven track record of producing high-quality machinery. So if you're in the market for a color steel roll forming machine, be sure to consider (brand name removed) and their range of high-quality products.

High-Quality Three-Layer Color Steel Roll Forming Machine for Sale

Three Layers Color Steel Roll Forming Machine Revolutionizes the Construction IndustryIn the fast-paced and evolving world of construction, the need for efficient and reliable equipment is paramount. With the introduction of the innovative Three Layers Color Steel Roll Forming Machine, construction companies now have a powerful tool at their disposal that promises to revolutionize the industry.Company Introduction:With a commitment to delivering cutting-edge solutions for the construction industry, our company has established a strong reputation as a leading manufacturer of roll forming machines. With years of experience and a dedication to innovation, we continue to push the boundaries of what is possible in construction technology.The Three Layers Color Steel Roll Forming Machine represents the latest addition to our range of advanced equipment. Designed to streamline the process of creating color steel sheets, this machine is set to transform the way construction projects are carried out.The Three Layers Color Steel Roll Forming Machine has been developed using state-of-the-art technology and the latest industry insights. We have meticulously crafted this machine with precision engineering, ensuring that it meets the highest standards of quality and reliability.Featuring a three-layer design, this machine is capable of forming color steel sheets with remarkable efficiency. The unique triple-layer system allows for a faster production process, enabling construction companies to meet tight deadlines and optimize their operations.Furthermore, this machine is equipped with advanced controls and automation, which ensures a smooth and seamless operation. The user-friendly interface makes it easy for operators to set up and monitor the machine, while the automation capabilities reduce the risk of errors and increase productivity.One of the key advantages of the Three Layers Color Steel Roll Forming Machine is its versatility. It is capable of producing a wide range of color steel sheets with varying thickness and dimensions, making it suitable for a diverse array of construction projects. This flexibility allows construction companies to adapt to different requirements and specifications, without the need for multiple machines.Additionally, the Three Layers Color Steel Roll Forming Machine is designed with durability in mind. Built to withstand the rigors of heavy-duty use, this machine is a long-term investment for construction companies, offering reliable performance and minimal maintenance requirements.In a competitive industry where time is of the essence, the speed and efficiency of the Three Layers Color Steel Roll Forming Machine set it apart. By streamlining the production process, this machine enables construction companies to improve their workflow and increase their output, ultimately translating to cost savings and greater profitability.With the introduction of the Three Layers Color Steel Roll Forming Machine, construction companies now have access to a game-changing technology that promises to elevate their operations. As we continue to uphold our commitment to innovation and excellence, we are proud to bring this cutting-edge solution to the construction industry, empowering our clients to achieve new heights of success.In conclusion, the Three Layers Color Steel Roll Forming Machine represents a significant advancement in construction technology, offering unmatched efficiency, versatility, and reliability. As the industry continues to evolve, this machine is poised to become a vital asset for construction companies seeking to gain a competitive edge. With its innovative design and unrivaled performance, the Three Layers Color Steel Roll Forming Machine is a testament to our company's dedication to shaping the future of construction.

High-Quality Steel Roll Forming Machine for Efficient Production

Steel Roll Forming Machine Helps Company Increase Production EfficiencySteel roll forming machines have revolutionized the way companies in the manufacturing industry produce high-quality steel products. With the aid of advanced technology and precision engineering, these machines have made it possible for companies to increase their production efficiency while reducing time and labor costs.One company that has greatly benefited from the use of a steel roll forming machine is {}. They have recently invested in a state-of-the-art steel roll forming machine, which has significantly improved their production capabilities and overall product quality.The {} company is a leading manufacturer of steel components for the construction and automotive industries. With a strong focus on innovation and quality, they have established themselves as a reputable and reliable supplier of steel products to their clients.The decision to invest in a steel roll forming machine was driven by the company’s commitment to staying ahead of the competition in a highly competitive market. By upgrading their manufacturing equipment, they aimed to increase their production capacity and improve the precision and consistency of their steel products.The steel roll forming machine acquired by {} is a cutting-edge piece of equipment that is designed to transform flat and coiled steel into a variety of shapes and profiles with remarkable efficiency and precision. This enables the company to produce a wide range of steel components, including beams, channels, angles, and custom profiles, which are all crucial for their clients' construction and automotive projects.One of the key advantages of the steel roll forming machine is its ability to produce long-length and continuous sheet metal components with uniform thickness and complex shapes. This eliminates the need for additional welding or assembly, which not only streamlines the manufacturing process but also enhances the structural integrity of the final products.With the new steel roll forming machine in place, {} has reported a significant increase in their production capacity, enabling them to fulfill larger orders and meet tighter deadlines. This has allowed the company to expand their client base and take on more complex and demanding projects, ultimately leading to an increase in revenue and profitability.Furthermore, the precision and consistency achieved through the use of the steel roll forming machine have resulted in a reduction in material wastage and rework, ultimately leading to cost savings for the company. The high-quality steel products produced by the machine have also improved the company’s reputation and reliability among their clients, leading to increased customer satisfaction and repeat business.In addition, the implementation of the steel roll forming machine has had a positive impact on the company’s employees, who have benefited from the automation and streamlining of the manufacturing process. The machine has reduced the physical labor required for producing steel components, creating a safer and more efficient working environment for the employees.Looking ahead, {} is committed to further leveraging the capabilities of their steel roll forming machine to explore new opportunities in the market and drive continuous improvement in their manufacturing processes. With a strong focus on innovation and quality, they are confident that the investment in the steel roll forming machine will continue to yield positive results for the company in the years to come.In conclusion, the acquisition of a steel roll forming machine has enabled {} to enhance their production efficiency, increase their product quality, and improve their competitiveness in the market. By investing in advanced manufacturing technology, the company has positioned itself for sustainable growth and success in the industry.

Revolutionary Technology Takes Color Steel Profile Manufacturing to the Next Level

Color Steel Profile Manufacturing Machine: Revolutionizing the Construction IndustryIn an era where technological innovations continue to transform various industries, the construction sector is not far behind. One such groundbreaking development is the introduction of the Color Steel Profile Manufacturing Machine, a game-changer that has revolutionized the steel manufacturing process. This cutting-edge equipment has not only improved efficiency but has also enhanced product quality, making it a preferred choice for numerous construction projects worldwide.The Color Steel Profile Manufacturing Machine, developed by an industry-leading company specializing in steel manufacturing equipment, has gained tremendous popularity within a short span of time. Founded in [year of establishment], the company has quickly emerged as a frontrunner in this niche market due to their relentless commitment to research and development, customer-centric approach, and dedication to delivering innovative solutions.The color steel profile manufacturing process begins with the raw materials. The machine can work with a range of materials, including galvanized steel, stainless steel, and aluminum, providing flexibility to cater to diverse project requirements. The company's proficiency in material selection and customization allows them to develop profiles that are not only aesthetically pleasing but also durable and resilient, ensuring longevity and resistance to external factors such as corrosion and weather fluctuations.One of the key advantages of the Color Steel Profile Manufacturing Machine is its advanced automation capabilities. This state-of-the-art equipment is equipped with sophisticated sensors, precision controllers, and cutting-edge software, enabling it to operate with minimal human intervention. This reduces the risk of errors, optimizes production time, and enhances overall efficiency. The machine's automated processes also contribute to cost reduction, as it eliminates the need for extensive manual labor.In addition to its automation capabilities, the Color Steel Profile Manufacturing Machine boasts remarkable precision and accuracy in profile creation. The company's team of experienced engineers and technicians ensures that each profile is meticulously designed and manufactured to meet the highest industry standards. The machine's advanced technology enables it to produce profiles with consistent dimensions, sharp edges, and smooth finishes, guaranteeing a flawless final product.Furthermore, the Color Steel Profile Manufacturing Machine prioritizes environmental sustainability. The company's commitment to green manufacturing practices is reflected in the machine's energy-efficient operations. By employing energy-saving technologies and optimizing resource utilization, the machine minimizes its carbon footprint, making it an eco-friendly choice for environmentally conscious construction projects.The versatility of the Color Steel Profile Manufacturing Machine is yet another notable feature. With the ability to produce a wide range of profiles, such as roofing sheets, wall panels, floor decking, and ceiling systems, this equipment caters to the diverse needs of the construction industry. Its adaptability allows architects and builders to bring their creative visions to life, facilitating the realization of unique and striking architectural designs.As the construction industry continues to evolve, the demand for efficient and high-quality steel manufacturing equipment is on the rise. The Color Steel Profile Manufacturing Machine stands at the forefront of this technological leap, offering a myriad of benefits to various stakeholders, including manufacturers, contractors, and end-users. Its advanced features, precision engineering, eco-friendly operations, and versatility make it an indispensable tool for the modern construction industry.In conclusion, the Color Steel Profile Manufacturing Machine is a remarkable innovation that has transformed the steel manufacturing process. With its advanced automation, precision engineering, environmental sustainability, and versatility, this equipment has become an indispensable asset for construction projects worldwide. As the industry evolves, this game-changing machine continues to redefine the future of steel profile manufacturing, offering endless possibilities for architects, builders, and construction companies alike.

Efficient and Reliable Color Steel Profile Manufacturing Machine Unveiled in Latest News

Color Steel Profile Manufacturing Machine Revolutionizes the IndustryIn an era of technological advancements, the manufacturing industry is witnessing a significant transformation. One such revolutionary innovation is the Color Steel Profile Manufacturing Machine, which has emerged as a game-changer for the steel profile manufacturing sector. With its advanced features and cutting-edge technology, this machine has the potential to revolutionize the way steel profiles are produced.Designed and developed by the renowned company [], the Color Steel Profile Manufacturing Machine combines precision engineering with state-of-the-art automation. This machine is equipped with the latest computer numerical control (CNC) technology, allowing for precise and efficient production of color steel profiles. By automating various processes, it eliminates the need for manual labor, reducing the potential for errors and improving productivity.One of the key features of this machine is its ability to produce color steel profiles of various shapes and sizes. Whether it is C-sections, Z-sections, or custom profiles, this machine can seamlessly manufacture them. This flexibility enables manufacturers to cater to a wide range of customer requirements, providing them with tailor-made solutions.The Color Steel Profile Manufacturing Machine is also equipped with a user-friendly interface, making it easy to operate and allowing for quick adjustments and setup changes. This feature enhances productivity as it reduces the time taken for machine setup and provides operators with a hassle-free working experience.Furthermore, this machine incorporates advanced safety features to ensure a secure working environment. With its automated sensor systems, it can detect any deviations from normal operations and promptly alert operators. This proactive approach to safety minimizes the risk of accidents and ensures the well-being of the workforce.One of the major advantages of this machine is its cost-effectiveness. By automating the manufacturing process, it significantly reduces labor costs and improves efficiency. Additionally, the precision and accuracy of the machine's output result in minimal material wastage, thereby reducing overall production costs. This cost-effectiveness makes it an attractive investment for steel profile manufacturers seeking to optimize their production processes.The Color Steel Profile Manufacturing Machine is not limited to the steel profile industry alone. Its applications extend to various sectors such as construction, infrastructure, and automotive. With the growing demand for steel profiles in these industries, this machine opens up new avenues for manufacturers to meet the market's needs efficiently.The environmental impact of this machine cannot be overlooked either. With the emphasis on sustainable practices, the Color Steel Profile Manufacturing Machine is designed to minimize energy consumption and reduce carbon emissions. Using advanced technology, it ensures that the manufacturing process is eco-friendly, aligning with the global efforts towards a greener future.In summary, the Color Steel Profile Manufacturing Machine revolutionizes the industry with its advanced features, automation, and cost-effectiveness. It caters to the diverse requirements of steel profile manufacturers and expands their capabilities to meet customer demands. With its user-friendly interface, safety features, and environmental benefits, this machine represents a significant leap forward in the manufacturing sector. As the industry continues to evolve, innovations like the Color Steel Profile Manufacturing Machine will play a crucial role in shaping its future.

Discover the Efficiency of Steel Profile Forming Equipment for Your Construction Needs

Title: Color Steel Profile Forming Equipment Revolutionizes the Steel Manufacturing IndustryIntroduction:In the age of rapid industrialization and technological advancements, the steel manufacturing industry has always been at the forefront. One such development that promises to revolutionize this sector is the Color Steel Profile Forming Equipment, a cutting-edge innovation that is set to transform the way steel profiles are manufactured.Color Steel Profile Forming Equipment is the brainchild of a renowned company (brand name removed), a global leader in industrial equipment manufacturing. Their relentless pursuit of innovation has culminated in this groundbreaking machinery, which offers unparalleled efficiency and precision in the production of color steel profiles.Optimized Manufacturing Process:The Color Steel Profile Forming Equipment boasts an array of modern features that streamline the steel profile manufacturing process and enhance overall productivity. Equipped with advanced computer numerical control (CNC) systems and advanced software, this equipment offers precise control over all parameters, resulting in profiles with exceptional dimensional accuracy.This cutting-edge technology eliminates the need for manual measurements and adjustments, significantly reducing human error and enhancing the overall quality of the manufactured profiles. The automated nature of this innovative equipment enables seamless integration with other factory machinery, resulting in a more efficient and synchronized production line.Diverse Applications:Color Steel Profile Forming Equipment caters to various industries, each with their unique requirements for steel profiles. From prefab construction and industrial manufacturing to infrastructure development and automotive production, this versatile machinery can produce a wide range of profiles to meet specific dimensional and design needs.The equipment's customizable nature allows manufacturers to effortlessly switch between different profile designs and dimensions, providing flexibility that caters to market demands. This adaptability ensures that the produced profiles are suited to each client's specifications, facilitating a broad scope of industrial applications.Exceptional Performance:Color Steel Profile Forming Equipment boasts a high-speed production rate, enabling manufacturers to meet stringent deadlines while maintaining exceptional quality standards. Equipped with cutting and forming tools that undergo regular maintenance and replacement, this machinery ensures accurate and precise shaping of steel profiles.The equipment's energy-efficient design reduces power consumption, leading to cost savings for manufacturers. Its durability and robust structure also minimize downtime, increasing overall operational efficiency and promoting sustainable production practices.Safety Features and Regulations:Safety is an utmost priority in any industrial setting, and Color Steel Profile Forming Equipment incorporates multiple safety features to ensure the well-being of workers. Emergency stop buttons and safety sensors guarantee prompt response and immediate shutdown in the event of any hazardous situation.Furthermore, the equipment adheres to all necessary safety regulations and standards, providing peace of mind to manufacturers and workers alike. A well-structured training program accompanies the installation of the machinery, ensuring operators are well-versed in its operation and safety guidelines.Conclusion:The introduction of Color Steel Profile Forming Equipment marks a significant milestone in the steel manufacturing industry. With its advanced technology, exceptional performance, and diverse applications, this machinery promises to revolutionize the production of color steel profiles.As the manufacturing sector continues to evolve, companies must embrace innovations like the Color Steel Profile Forming Equipment to remain competitive. With its ability to enhance productivity, improve quality, and promote safety, this groundbreaking machinery is set to shape the future of the steel manufacturing industry.