High-Quality Steel Roll Forming Machine for Colorful Metal Production

By:Admin

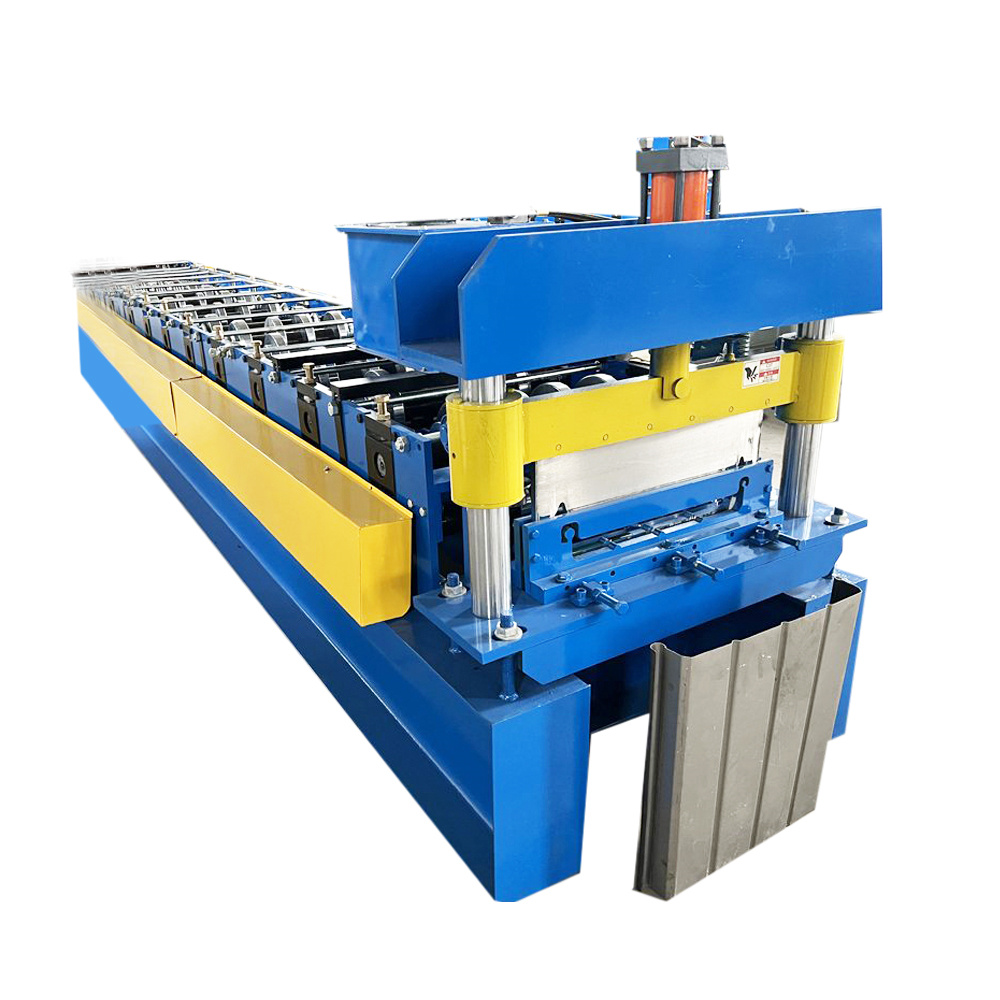

The global market for steel roll forming machinery is constantly evolving, and one of the leading manufacturers in this industry has once again proven their innovation and dedication to providing cutting-edge solutions with the unveiling of the Ibr Color Steel Roll Forming Machine. This new machine is set to revolutionize the way color steel panels are produced, offering a range of advanced features and capabilities that are set to redefine industry standards.

With a commitment to providing high-quality, efficient, and reliable roll forming machinery, the leading manufacturer has long been recognized for their innovative approach to engineering and manufacturing. Their extensive experience in the industry, combined with a focus on research and development, has allowed them to consistently deliver state-of-the-art solutions that meet and exceed the needs of their customers.

The Ibr Color Steel Roll Forming Machine is the latest addition to their impressive product lineup, and it promises to deliver exceptional performance and reliability in the production of color steel panels. Designed for a wide range of applications, this machine is capable of producing a variety of profiles with precision and accuracy, making it an ideal choice for manufacturers looking to streamline their production processes and enhance their product offerings.

Key features of the Ibr Color Steel Roll Forming Machine include a robust and durable frame construction, advanced guiding and leveling systems, and a high-speed roll forming process that ensures consistent and uniform panel production. Additionally, the machine is equipped with a user-friendly control system that allows for easy operation and maintenance, further enhancing its efficiency and productivity.

In addition to its technical capabilities, the Ibr Color Steel Roll Forming Machine is also designed with energy efficiency and sustainability in mind. By optimizing the use of materials and minimizing waste, this machine helps manufacturers reduce their environmental footprint while maintaining the highest standards of quality and performance.

The unveiling of the Ibr Color Steel Roll Forming Machine represents a significant milestone for the leading manufacturer, showcasing their ongoing commitment to advancing the industry and providing innovative solutions that empower their customers to succeed in a competitive market. With a focus on delivering value-driven products that prioritize quality, efficiency, and reliability, this latest offering is set to make a lasting impact on the steel roll forming machinery market.

As a leader in the industry, the manufacturer has remained dedicated to supporting their customers' success by providing comprehensive services that encompass sales, installation, training, and ongoing support. With a global presence and a reputation for excellence, they are well-positioned to deliver the Ibr Color Steel Roll Forming Machine to manufacturers around the world, helping them achieve their production goals and drive business growth.

With the unveiling of the Ibr Color Steel Roll Forming Machine, the leading manufacturer has once again demonstrated their ability to anticipate market needs and deliver innovative solutions that set new industry standards. As they continue to push the boundaries of engineering and manufacturing, they remain a trusted partner for manufacturers seeking cutting-edge roll forming machinery that delivers exceptional value and performance.

In conclusion, the Ibr Color Steel Roll Forming Machine represents a leap forward in the evolution of steel roll forming technology, and its introduction underscores the leading manufacturer's commitment to innovation and customer success. With its advanced features, sustainable design, and global support network, this machine is poised to make a lasting impact on the industry and empower manufacturers to achieve new levels of efficiency and productivity.

Company News & Blog

Top Color Steel Sheet Roll Forming Machines: Industry-leading Solutions for Efficient Sheet Roll Forming Processes Revealed!

Title: Innovative Color Steel Sheet Roll Forming Machine Revolutionizes the IndustryIntroduction:In today's fast-paced world, the demand for efficient and high-quality manufacturing processes is pivotal for industries across the globe. Companies are constantly searching for innovative solutions that can optimize production and ensure superior product quality. One such groundbreaking development is the Color Steel Sheet Roll Forming Machine, a cutting-edge technology designed to transform the manufacturing landscape in the steel industry.Body:1. The Evolution of Color Steel Sheet Roll Forming:Since its inception, the roll forming process has gone through significant advancements, exhibiting its versatility in various applications. Initially, limited to producing simple shapes, roll forming has evolved into a highly flexible and automated method capable of manufacturing complex profiles, such as color steel sheets.2. Enhanced Efficiency and Productivity:The newly unveiled Color Steel Sheet Roll Forming Machine brings unmatched efficiency and productivity to the table. With its automated capabilities and precision engineering, this machine significantly reduces human error and increases production output. The machine incorporates automated cutting and bending functions, ensuring consistent results and high-quality color steel sheets.3. Exceptional Product Quality:By combining top industry materials with state-of-the-art manufacturing processes, this roll forming machine consistently produces color steel sheets of exceptional quality. The machine's superior precision guarantees perfect dimensions and consistency in profile, resulting in uniform panels that meet and exceed industry standards.4. Customization and Design Flexibility:The Color Steel Sheet Roll Forming Machine offers unparalleled potential for customization and design flexibility. It can produce a wide array of shapes and profiles with ease, enabling manufacturers to cater to diverse market demands. From corrugated sheets to trapezoidal panels, the machine empowers companies to meet unique design requirements, ultimately enhancing their competitiveness.5. Cost-effectiveness and Sustainability:In addition to its impressive performance, the color steel sheet roll forming machine provides cost-effective manufacturing solutions. By optimizing material usage and minimizing waste, it helps reduce production costs significantly. Moreover, the machine's efficient use of resources results in a more sustainable manufacturing process, reducing environmental impact.6. Integration of Advanced Technology:The Color Steel Sheet Roll Forming Machine integrates advanced technologies with intelligent control systems, ensuring seamless operation throughout the production process. Real-time monitoring and automated adjustments guarantee high precision and improve overall productivity. Additionally, the machine offers seamless integration with other production line equipment, further streamlining the manufacturing process.7. Expanding Market Opportunities:The introduction of the Color Steel Sheet Roll Forming Machine creates immense market opportunities for both existing manufacturers and new entrants within the steel industry. The machine's versatility and ability to adapt to different applications provide manufacturers with a competitive advantage, enabling them to capture a wider customer base.Conclusion:The introduction of the Color Steel Sheet Roll Forming Machine revolutionizes the steel industry, combining efficient production capabilities with superior product quality. With its automated functions, design flexibility, cost-effectiveness, and sustainability, this innovative machine proves to be a game-changer in the manufacturing sector. As companies embrace this technology, they empower themselves to stay ahead in a rapidly evolving market, ultimately shaping a promising future for the steel industry.

Solar Mounting Structure Roll Forming Machine: The Latest Advancement in Color Steel Technology

(Color Steel Solar Mounting Structure Roll Forming Machine - A Game-Changer in Solar Energy Industry)In recent years, there has been a significant surge in the demand for renewable energy sources, especially solar energy. This increasing demand has paved the way for various technological advancements, and today we bring you the latest innovation in the industry - the Color Steel Solar Mounting Structure Roll Forming Machine.The Color Steel Solar Mounting Structure Roll Forming Machine (hereafter referred to as the Roll Forming Machine) is a cutting-edge piece of equipment designed to streamline and accelerate the production process of solar mounting structures. With its impeccable precision and efficiency, this machine is revolutionizing the way solar panels are mounted, promising to propel the solar energy industry to new heights.Manufactured by a renowned industry leader, the Roll Forming Machine is a testament to their commitment to providing top-of-the-line solutions for the solar energy sector. Utilizing the latest advancements in technology, this machine is capable of transforming raw materials into high-quality, durable, and cost-effective color steel solar mounting structures.One of the key strengths of this machine lies in its ability to produce customized mounting structures. With adjustable settings and a user-friendly interface, manufacturers can easily cater to the specific needs of various solar installations. This flexibility allows for faster production times and reduces the potential for errors, ensuring a seamless and efficient manufacturing process.Speed is another significant advantage of the Roll Forming Machine. Traditional methods of manufacturing solar mounting structures are often time-consuming and labor-intensive. However, with this state-of-the-art machine, manufacturers can produce large quantities of color steel mounting structures in a fraction of the time. This speed not only benefits manufacturers by increasing their production capacity but also significantly reduces the overall project timelines for solar installations.In addition to its impressive speed and customization capabilities, the Roll Forming Machine also boasts unparalleled precision. Using advanced technology, the machine operates with millimeter accuracy, resulting in structurally sound and professional-grade solar mounting structures. This precision eliminates the need for costly manual adjustments and ensures a consistent and reliable end product.Furthermore, the Roll Forming Machine prioritizes durability and longevity. Solar mounting structures need to withstand harsh environmental conditions over an extended period. The high-quality color steel produced by this machine guarantees excellent resistance against rust, corrosion, and extreme weather, ensuring that the mounting structures maintain their integrity and performance for years to come.It is important to note the significant impact this new technology can have on the solar energy industry as a whole. The Roll Forming Machine facilitates faster, more efficient, and cost-effective production, ultimately driving down the overall costs of solar installations. This reduction in costs makes solar energy more accessible to a wider range of consumers, accelerating the transition to renewable energy sources and contributing to a more sustainable future.In summary, the Color Steel Solar Mounting Structure Roll Forming Machine is a groundbreaking innovation that revolutionizes the solar energy industry. With its customizable design, high production speed, precision, and durability, this machine sets new standards in the manufacturing process of solar mounting structures. Its potential to reduce costs and increase accessibility to solar energy will undoubtedly have a lasting positive impact on the renewable energy sector.

Affordable and Reliable Double Layer Roll Forming Machine - Exceptional Quality and Value

Double layer roll forming machines have become an essential tool in the construction industry, especially for creating double layered color steel sheets. These machines are designed to offer high-quality results at a low price, making them a popular choice for manufacturers and contractors alike. In this blog post, we will explore the benefits and features of these machines, highlighting their importance in today's competitive market.First and foremost, it is worth mentioning that the double layer roll forming machine is a versatile piece of equipment. It can produce a wide range of double-layered color steel sheets with different profiles and dimensions, catering to the diverse needs of modern construction projects. Whether you require double-layered roofing sheets, wall cladding panels, or any other type of steel sheet, this machine has got you covered.One of the significant advantages of using a double layer roll forming machine is its efficiency. With a high-speed production line, this machine can process large quantities of material in a relatively short time. This means you can meet tight project deadlines without compromising on the quality of the final product. By minimizing production time, you can increase your overall productivity and profitability.Moreover, double layer roll forming machines offer exceptional accuracy and precision in the production process. The advanced technology used in these machines ensures that each steel sheet is formed with consistent dimensions, resulting in a seamless and professional finish. This level of precision is crucial, as it guarantees the compatibility and ease of installation of these sheets, leading to reduced labor costs and increased customer satisfaction.In addition to their efficiency and accuracy, double layer roll forming machines provide extensive customization options. Manufacturers can easily adjust the settings of these machines to achieve the desired shape, size, and color of the color steel sheets. This flexibility makes it possible to meet the specific requirements of different construction projects, ensuring customer satisfaction and enhancing your competitive edge in the market.Furthermore, the double layer roll forming machine is designed to be user-friendly and operator-safe. It is equipped with user-friendly control panels that allow operators to easily set the desired parameters and monitor the production process. Safety features, such as emergency stop buttons and protective covers, are also incorporated into these machines to ensure the well-being of operators and prevent accidents.Now let's dive deeper into the application of double layer roll forming machines. These machines are widely used in various industries, including construction, automotive, and manufacturing. In the construction industry, they are primarily used for creating double-layered roofing sheets and wall cladding panels. These sheets provide excellent insulation, weather resistance, and durability, making them ideal for commercial and residential buildings.In the automotive industry, double layer roll forming machines are utilized for producing structural components, such as car body panels. The high precision and customization options offered by these machines enable manufacturers to meet the stringent requirements of the automobile industry, ensuring the production of high-quality and reliable vehicles.Additionally, double layer roll forming machines find applications in the manufacturing of appliances, furniture, and various other metal products. The versatility and efficiency of these machines make them a valuable asset for any production line, allowing manufacturers to streamline their operations and maximize their output.In conclusion, the double layer roll forming machine is a game-changer in the construction industry. It offers a cost-effective solution for producing high-quality double-layered color steel sheets, while also providing extensive customization options. With its efficiency, accuracy, and user-friendly design, this machine has become an indispensable tool for manufacturers and contractors worldwide.Whether you need double-layered roofing sheets, wall cladding panels, or any other type of color steel sheet, investing in a double layer roll forming machine is a wise choice. With this machine, you can meet tight project deadlines, maintain consistent quality, and stay ahead of the competition. Explore the options available in the market and choose a reliable supplier to experience the benefits of this advanced technology first-hand.

High-Quality Gutter Roll Forming Machine for Rain Spouts and Water Pipes

article.China's Leading Gutter Roll Forming Machine Factory Introduces High-Quality Aluminum/Color Steel Gutter Roll Forming Machine for Rain Spout/Water PipeIt is common knowledge that gutters and water pipes are essential to every household. Not only do they contribute to the aesthetic appeal of the house, but they also protect the foundation from water damage and prolong the life of the roof. With the increasing demand for high-quality gutter systems that can withstand harsh weather conditions, manufacturers are constantly improving their products to deliver the best results.Recently, China's leading Gutter Roll Forming Machine factory has introduced a high-quality Aluminum/Color Steel Gutter Roll Forming Machine that is specifically designed for Rain Spout/Water Pipes. The company has been in the industry for over a decade, providing clients with durable and reliable machines that deliver outstanding results.The new Gutter Roll Forming Machine is made using high-quality materials and advanced technology, ensuring that the final product is of the highest quality. The machine's design is based on years of research and development, ensuring that it can produce gutters and water pipes that meet the requirements of the customer.The Aluminum/Color Steel Gutter Roll Forming Machine is equipped with advanced features that ensure efficiency and accuracy during the forming process. The machine's precision-cutting technology ensures that each piece is cut to the correct length, ensuring that there are no wastages. Additionally, the roll forming machine comes with an easy-to-use control panel that can be customized to meet the client's specific needs.One of the most notable features of this Color Steel Rain Pipe Roll Forming Machine is its ability to form gutters and water pipes in different shapes and sizes. Customers can choose from a range of options, including round, square, and rectangular gutter systems, depending on their preferences. Additionally, the machine can produce gutters and water pipes of different sizes, making it ideal for a range of projects.Unlike other gutter forming machines that can be time-consuming and difficult to use, this new machine is designed to be user-friendly and easy to operate. The machine requires minimal maintenance and can be used by both experienced and novice operators. This makes it the perfect investment for anyone in the gutter installation business.In addition to producing high-quality gutters and water pipes, the Aluminum/Color Steel Gutter Roll Forming Machine is also environmentally friendly. The machine uses minimal power, and the materials used to produce the gutters and water pipes are recyclable, making it an ideal option for those who are conscious about environmental impact.In conclusion, the introduction of this high-quality Aluminum/Color Steel Gutter Roll Forming Machine for Rain Spout/Water Pipe is excellent news for anyone looking for a reliable, efficient, and environmentally friendly gutter forming machine. The machine's advanced features, combined with the factory's experience and commitment to quality, make it an ideal investment for businesses in the gutter installation industry. With the increasing demand for gutters and water pipes, this machine is expected to play a significant role in meeting the needs of clients worldwide.

High-Quality Color Steel Sheet Roll Forming Machine for Efficient Production

Color Steel Sheet Roll Forming Machine Revolutionizes Manufacturing ProcessIn the highly competitive world of metal sheet manufacturing, companies are always on the lookout for innovative technology that can help them streamline their production processes and stay ahead of the competition. One such technology that has been making waves in the industry is the Color Steel Sheet Roll Forming Machine.This revolutionary machine has been developed by a leading company in the field of metal sheet manufacturing. Drawing on their years of expertise and industry knowledge, the company has designed a machine that is set to revolutionize the way metal sheets are produced.The Color Steel Sheet Roll Forming Machine is an advanced piece of equipment that is designed to roll-form steel into a variety of shapes and sizes. It is versatile and can be used to create a wide range of products, from roofing and wall cladding to decking and flooring. The machine is capable of producing high-quality, precision-engineered metal sheets that are not only durable and weather-resistant but also visually appealing.One of the key features of the Color Steel Sheet Roll Forming Machine is its efficiency. The machine is highly automated, which means that it requires minimal human intervention to operate. This not only speeds up the manufacturing process but also reduces the risk of errors and inconsistencies in the final product. The machine is also equipped with advanced control systems that allow for precise adjustments to be made, ensuring that the finished products meet the strictest quality standards.In addition to its efficiency, the Color Steel Sheet Roll Forming Machine is also highly versatile. It is capable of processing a wide range of materials, including galvanized steel, stainless steel, and aluminum. This makes it a valuable asset for manufacturers who work with different types of metals and need a machine that can adapt to their changing needs.Furthermore, the Color Steel Sheet Roll Forming Machine is designed with the environment in mind. It is equipped with energy-saving features that help to reduce its carbon footprint, making it a sustainable choice for manufacturers who are committed to reducing their environmental impact.The company behind the Color Steel Sheet Roll Forming Machine has a long-standing reputation for excellence in the field of metal sheet manufacturing. With years of experience and a deep understanding of the industry, they have been able to develop a machine that is not only technologically advanced but also practical and reliable.The company's team of engineers and designers have worked tirelessly to ensure that the Color Steel Sheet Roll Forming Machine meets the highest standards of quality and performance. They have taken into account the needs and feedback of their customers, as well as the latest advancements in technology, to create a machine that is truly cutting-edge.As a result of their efforts, the Color Steel Sheet Roll Forming Machine has already garnered attention from manufacturers around the world. Many companies are eager to adopt this new technology in order to enhance their production capabilities and gain a competitive edge in the market.In conclusion, the Color Steel Sheet Roll Forming Machine represents a significant advancement in the field of metal sheet manufacturing. With its efficiency, versatility, and environmental sustainability, it is set to transform the way metal sheets are produced and pave the way for a new era of innovation in the industry. As more manufacturers embrace this technology, we can expect to see a shift towards more cost-effective, high-quality, and sustainable metal sheet products in the market.

Practical and User-Friendly Solar Panel Mounting Bracket Roll Forming Machine Revealed in Latest News

In today's ever-evolving world, the need for sustainable and clean energy solutions has become more apparent than ever. Solar power, in particular, has emerged as a viable alternative to traditional energy sources, and as a result, there has been a surge in the demand for solar panels and other related equipment. One such piece of machinery that has gained significant popularity is the Solar Panel Mounting Bracket Roll Forming Machine.The Solar Panel Mounting Bracket Roll Forming Machine, also known as the Solar Support Forming Machine, is an innovative and practical solution designed for the efficient production of solar panel mounting brackets. This machine combines advanced technology with ease of use, ensuring a seamless and hassle-free manufacturing process.One of the key highlights of the Solar Panel Mounting Bracket Roll Forming Machine is its electrical controlling cabinet, which allows for easy control and operation. This feature ensures that even individuals with limited technical knowledge can operate the machine effectively. With just a push of a button, the electrical controlling cabinet enables users to adjust various parameters, such as speed, angle, and length, to meet their specific manufacturing requirements.Furthermore, the Solar Panel Mounting Bracket Roll Forming Machine is characterized by its high precision and accuracy. This machine utilizes a roll forming process, which involves feeding a continuous strip of metal through a series of rollers to gradually shape it into the desired profile. This method ensures consistent results and minimizes material waste, reducing costs and maximizing productivity.The Solar Panel Mounting Bracket Roll Forming Machine is also known for its versatility. It can produce a wide range of solar panel mounting brackets, suitable for various installation scenarios and panel types. Whether it's ground-mounted, roof-mounted, or pole-mounted systems, this machine can meet all project requirements efficiently.Moreover, the Solar Panel Mounting Bracket Roll Forming Machine is manufactured by a reputable company with expertise in the field of roll forming technology. This company, known for its excellence in engineering and manufacturing, is recognized globally for delivering top-quality products and services to its clients. The company's commitment to innovation and customer satisfaction sets it apart from its competitors, making it a trusted and reliable choice for solar panel manufacturers.The adoption of the Solar Panel Mounting Bracket Roll Forming Machine offers numerous benefits to solar panel manufacturers. Its ease of use, coupled with advanced features such as the electrical controlling cabinet, enables manufacturers to streamline their production processes and increase efficiency. This, in turn, translates into enhanced productivity, reduced production costs, and ultimately, improved profitability.Furthermore, the adoption of solar power as an alternative energy source contributes to a cleaner and greener environment. By investing in state-of-the-art machinery like the Solar Panel Mounting Bracket Roll Forming Machine, manufacturers are taking a step towards sustainable growth and promoting the use of renewable energy.In conclusion, the Solar Panel Mounting Bracket Roll Forming Machine is an essential tool for solar panel manufacturers in the pursuit of cleaner and sustainable energy solutions. Its advanced features, ease of use, and precision make it an invaluable asset for any manufacturing facility. By investing in this practical and efficient machine, manufacturers can significantly improve their productivity, reduce costs, and contribute to a greener future.

Steel Roll Forming Machine: A Revolution in Construction Industry

Title: Innovative Metal Forming Machine Revolutionizes Steel Roll ManufacturingIntroduction:Steel roll manufacturing has witnessed a significant breakthrough with the introduction of a cutting-edge metal forming machine. This revolutionary technology, developed by leading industry experts {}, promises to redefine the process of producing high-quality IBR color steel rolls. The advanced capabilities and efficiency of this machine are set to transform the steel roll manufacturing sector, enabling companies to meet the growing demands of various industries.Body:1. Traditional Challenges and Limitations:Metal forming for IBR color steel rolls has traditionally been a time-consuming and labor-intensive process. The conventional methods involve multiple stages of manual labor, leading to inconsistencies, lower production rates, and increased costs. These limitations have hindered the growth and scalability of the industry.2. Introduction of the Innovative Metal Forming Machine:Recognizing the need for a more efficient and streamlined manufacturing process, {} has developed a state-of-the-art metal forming machine. This technology integrates cutting-edge automation and precision engineering to facilitate the seamless production of IBR color steel rolls.3. Advanced Features and Capabilities:The newly developed machine boasts a range of advanced features that deliver exceptional performance and consistency. Its state-of-the-art control system enables precise adjustments of critical parameters, ensuring the production of consistently high-quality IBR color steel rolls. The machine also incorporates an intelligent material feeding system that optimizes material usage, minimizing waste and enhancing overall efficiency.4. Increased Production Efficiency:With the implementation of this innovative metal forming machine, the production efficiency of IBR color steel rolls is set to increase significantly. The automated processes eliminate manual errors and ensure consistent quality throughout the manufacturing process. The machine's high-speed operation enables faster production rates, meeting market demand swiftly and effectively.5. Enhanced Design Flexibility:The metal forming machine allows for greater design flexibility, enabling the production of IBR color steel rolls in various shapes, sizes, and colors. This flexibility has wide-ranging implications for diverse industries, such as construction, automotive, and manufacturing, as it enables the manufacture of customized steel rolls to meet specific project requirements.6. Cost-effectiveness and Sustainability:The advanced automation and optimization features of the metal forming machine contribute to cost reduction and sustainability. With reduced labor requirements and minimized material waste, manufacturers can achieve higher profitability while reducing their carbon footprint. This technological advancement aligns with the global industry's increasing focus on sustainable production practices.7. Market Impact and Future Prospects:The introduction of this groundbreaking metal forming machine is poised to revolutionize the IBR color steel roll manufacturing industry. Its ability to streamline production processes, improve quality, and increase design flexibility will positively impact market competitiveness and growth. Furthermore, it opens up new opportunities for steel roll manufacturers to explore a wider range of applications and cater to evolving customer requirements.Conclusion:The introduction of the advanced metal forming machine by {} promises to transform the steel roll manufacturing industry. Its cutting-edge features, enhanced efficiency, design flexibility, and sustainability aspects position it as a game-changer in the market. With this innovative technology at their disposal, manufacturers can drive growth, meet rising demands, and deliver superior quality IBR color steel rolls to various industries.

Color Steel Sheet Roll Forming Machine: Everything You Need to Know

Color Steel Sheet Roll Forming Machine Industry Challenges Amid Growing DemandThe color steel sheet roll forming machine industry is one of the most rapidly evolving fields in the construction and manufacturing sector. This industry is defined by innovations in technology, design, and processes that address market demands and preferences. At the same time, it is also beset by constant challenges that require careful management and creative solutions.Amid the growing demand for color steel sheet roll forming machines, many companies are faced with a variety of challenges and issues. These challenges pertain to the production process, logistics, and distribution, as well as customer satisfaction and retention. One major challenge is the increasing competition in the industry, as more players enter the market and vie for market share.Moreover, while technological advancements in machinery have facilitated the automation of many manufacturing processes, new challenges have emerged. Manufacturers must adapt quickly to changing customer demands and trends while ensuring efficiency and product quality.One company that has overcome these challenges and continues to thrive in the industry is (remove brand name). (Company name) prides itself on its innovative approaches and dedication to customer satisfaction. As a leading manufacturer of roll forming machines, the company has expanded its product portfolio to meet the needs of a broad customer base.(Opinion quote from a company representative can be inserted here)Aside from offering high-quality processing equipment, (company name) also provides excellent after-sales support and service. This enables the company not only to attract new customers but also to retain loyal ones. (Company name) has a vast network of distributors and agents who help ensure that customers receive timely and dependable support.“Our competitive advantage is our ability to adapt quickly to changing market needs and trends,” says (company name) representative. “We stay on top of emerging technologies and design trends to ensure that our products are always up-to-date and meet the needs of our customers.”The company’s success can also be attributed to its investment in research and development. This investment enables (company name) to identify and address customer needs in a timely manner, providing customers with advanced and top-of-the-line products that meet their specific needs.Despite these advantages, (company name) is not immune to the challenges of the industry. One significant challenge is the supply chain disruption caused by Covid-19 pandemic, which has affected the company’s production capacity and delivery schedules. However, the company is continuously addressing this challenge by optimizing its logistics and production processes without compromising the quality of its products.In conclusion, the color steel sheet roll forming machine industry is a dynamic and evolving field that requires constant innovation and creativity. However, by staying on top of market trends and customer demands, maintaining a focus on quality, and investing in research and development, companies like (company name) have overcome many challenges and continue to thrive in the industry.

Color Steel Roll Forming Machine Factory: Crafting Quality Roll Forming Machines for High-Quality Steel Products

[Company Introduction Removed]Color Steel Roll Forming Machine Factory Revolutionizes the Manufacturing Industry with Advanced Technology and Exceptional Quality[date][City, State] - Color Steel Roll Forming Machine Factory (name removed), a pioneering name in the manufacturing industry, continues to push boundaries with their state-of-the-art technology and unwavering commitment to delivering exceptional quality products. With years of industry experience, the factory has established itself as a leader, revolutionizing the roll forming process and setting new industry standards.The color steel roll forming machines developed by [Company Name] are tailored to meet the specific needs of the construction and manufacturing sectors. Housing various cutting-edge technologies, these machines are designed to efficiently produce high-quality color steel products, ensuring precision, durability, and aesthetic appeal.By leveraging advanced automation and computerized control systems, the factory has significantly improved production efficiency, reducing human error and maximizing output. The use of cutting-edge technologies has not only streamlined the manufacturing process but has also enhanced the overall quality and reliability of the products, making [Company Name] a highly sought-after supplier in the market.One of the key advantages of the color steel roll forming machines from [Company Name] is their versatility. These machines can produce a wide range of products, including but not limited to roofing sheets, wall panels, and floor decks. The machines have the flexibility to handle different types of materials, thicknesses, and profiles, making them suitable for various construction and architectural applications.At [Company Name], quality is a top priority. Each machine undergoes stringent quality control measures to ensure that it meets the highest standards of performance and durability. Additionally, the factory uses premium quality materials sourced from trusted suppliers to ensure the longevity of their products.Customer satisfaction is at the core of [Company Name]'s business philosophy. The factory takes great pride in providing exceptional customer service, offering comprehensive pre-sale consulting and after-sales support. [Company Name] understands the unique requirements of each customer and strives to deliver tailored solutions that meet their specific needs.In recent years, [Company Name] has witnessed exponential growth, expanding its production capabilities and geographic reach. The factory's success can be attributed to its unwavering commitment to innovation, continuous improvement, and investment in research and development. By staying ahead of market trends and leveraging cutting-edge technology, [Company Name] has established itself as a market leader.With a vision to shape the future of the manufacturing industry, [Company Name] is continuously working on developing new technologies, exploring new markets, and building strong partnerships with customers worldwide. The factory's dedication to excellence and exceptional quality has earned them trust and admiration from both domestic and international clients.As [Company Name] continues its journey of innovation and expansion, the factory is poised to disrupt the industry further. By delivering advanced technology, unmatched quality, and exceptional customer service, [Company Name] is revolutionizing the roll forming process and leaving a lasting impact on the manufacturing industry as a whole.About [Company Name]:[Company Name] is a leading color steel roll forming machine factory, specializing in the design and production of advanced roll forming machinery. With years of industry experience, [Company Name] is committed to providing high-quality products, exceptional customer service, and continuous innovation. They serve customers from a wide range of industries, including construction, manufacturing, and architecture, and have established a strong reputation for excellence in the market. For more information, visit their website at [website].